Drum shells have multiple components that determine their sound. These include shell material, drumhead choice, hoop choice, and the angle of their bearing edges.

Out of all those components, bearing edges on drum shells are the one that people don’t look into as much as they do the others. However, you should know how bearing edges work so that you can see how they affect a drum’s tone.

In this guide, we’re going to look at all the types of bearing edges that you can get. I’ll explain how their angles affect their tone, and I’ll give you a few tips on which bearing edges may be better for your style of drumming.

Contents

What are Drum Bearing Edges?

The drum bearing edge is the part of a drum shell where the drumhead rests on. The bearing edges can be found on the top and bottom of drum shells, and you’ll see them most clearly when you remove the drumheads and metal hoops.

All drums have bearing edges that were made with specific tones in mind. Many drummers prefer the sounds that certain bearing edges bring out from a drum, so they tend to use drum kits with their preferred style of bearing edge.

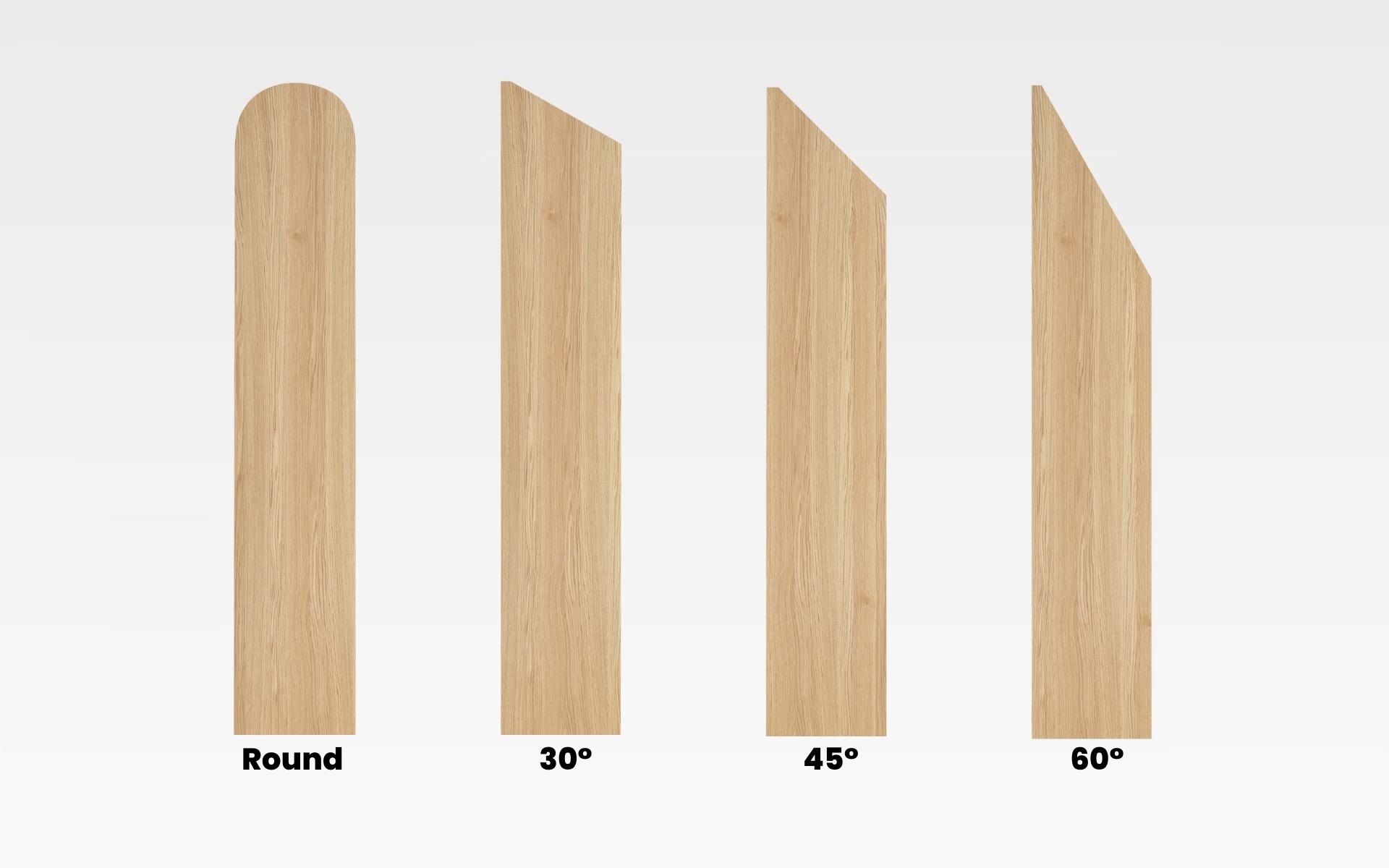

Some drum companies design bearing edges that are unique to their brand, but most bearing edges go along the same lines of being rounded at the top or having an angle at 30, 45, or 60 degrees.

The Importance of Bearing Edges

Bearing edges mainly affect the resonance and timbre of drums. While the drum shell material determines the sound quality of the drum, the bearing edge determines how that sound quality comes out of the drum when you play it.

When drum companies produce drum kits, they put a lot of effort into deciding which type of bearing edge to use to determine how the kit will sound.

There isn’t too much of a price gap between different kinds of bearing edges. The price differences between drums mainly have to do with shell material and hardware.

It’s important to understand bearing edges so that you have an idea of how the drums you’re buying will sound. No matter what heads and tuning you have, certain bearing edges will always bring similar tonal qualities out of different drums.

You may not like highly resonant toms, so you should know which bearing edges cause that quality to avoid them. You may love the sound of short toms with minimal sustain, so you should know which bearing edges will give you toms like that.

Different Drum Bearing Edge Angles and How They Affect Tone

Round Bearing Edges

Round bearing edges were the original type of bearing edges that most drum kits had in the 20th century. Because of this, they’re often associated with vintage tones.

Round bearing edges have the most contact between drumhead and shell, and this gives drums that have them very controlled tones with minimal attack.

Think of how Ringo Starr’s drums sounded in all of The Beatles tracks. That gives you a general idea of what drums with rounded bearing edges sound like.

Since their tones are more controlled, they often don’t require as much muffling as other drums do. That makes them great for drummers who like a clean tone that hasn’t been hampered with too much by external components.

Drums with rounded bearing edges are excellent options for jazz drums and old-school music like classic rock and blues.

These bearing edges aren’t near as popular as they used to be. So, it’s quite difficult to find mainline drum kits from the popular brands that have them on their shells.

30-Degree Bearing Edges

30-degree bearing edges have slightly more resonance and attack, thanks to having more room between the head and shell.

They’re also found on a lot of older drums, but many drum brands use them on their high-end drum kits today as well. Another name for these edges is Vintage Edges, which is why you’ll find them on high-end drums that are aiming to achieve a vintage drum tone.

Drums with these edges sing nicely and have a fair bit of projection, but they’re still more controlled than the sharper edges that are a lot more common.

These edges give much better attack to drums than roundover edges, but they still control the sustain a fair bit.

If you want a drum kit that has a unique vintage tone, look for one with 30-degree bearing edges. An excellent example would be the Gretsch Broadkaster. It’s a modern drum kit with amazing modern hardware, but the bearing edges are what give it its vintage-inspired tone.

45-Degree Bearing Edges

45-degree bearing edges are the most common type of bearing edges used for modern drum sets. They make drums sustain for long, and they bring out a wide array of dynamics.

If you love using drums that sing when you hit them hard, these are the ideal bearing edges to have on your kit. You can get even more sustain from 45-degree bearing edges if you mount the drums on hardware that enhances their resonance.

You’ll find the most variety when it comes to these bearing edges, considering that every drum brand has multiple sets in their product lines that use them.

45-degree bearing edges produce what is commonly referred to as the modern drum sound, so they’re excellent for all contemporary styles of music.

They’re a bit harder to tune due to the resonance and extensive overtones, so drums with these bearing edges often require a lot more muffling than the previous bearing edges we looked at.

Some drum shells have a dual 45-degree bearing edge design. These drums have even longer sustains with wider tuning ranges.

60-Degree Bearing Edges

60-degree bearing edges are another type of bearing edge that isn’t very common. Drums with these have plenty of attack, but almost no sustain.

You get an incredibly punchy sound from the drums that sings strongly when they’re struck, but then it fades away very quickly.

These bearing edges are amazing for metal and gospel drummers. They work well for drumming in styles where you play fast tom patterns around the kit. Since the sustain of the drums is so short, the notes don’t blend into each other, which is great.

If you play drum patterns like that with ringing toms, the sounds start to jumble and become muddy. So, less sustain is typically the better option, and 60-degree bearing edges work well for that.

Bearing Edge FAQs

How Are Bearing Edges Cut?

Drum manufacturers have special tables where they place the drum shells. These tables have a blade that can be positioned in different ways to cut out bearing edges as needed. Someone needs to sit and move the drum shell as the blade cuts out the bearing edge on the shell.

How Do You Clean Drum Bearing Edges?

You can clean a drum’s bearing edge is with a damp cloth. You simply need to remove the drumhead and rim so that the shell is bare, and then gently wipe down both the top and bottom bearing edges. You shouldn’t use any strong cleaning materials, as that won’t be good for the wood.

Bearing edges are quite protected when your drums are set up, so you should only be wiping away some dust or debris with the damp cloth.

If you do notice any imperfections such as nicks or small chippings, you can use a fine-grit sandpaper to lightly sand it away. You don’t want to change the profile of the bearing edge, but simply remove imperfections.

How Do You Check Drum Bearing Edges?

One of the best ways to check bearing edges is to put the bare drum shell on a flat surface and then take a light and shine it near the bottom of the shell while you rotate it.

While it’s rotating, an uneven bearing edge will have the light shine through the bottom of the shell. If this is the case, the uneven bearing edge may be the cause of the drum not being able to be tuned easily.

Uneven bearing edges aren’t the end of the world, but some are so bad that you’ll need to get them repaired.

Final Thoughts

Bearing edges should be your most important consideration if you plan on playing drums without any muffling. The type of tuning you can get from drums greatly depends on the angle of the wood where it meets the drumhead.

Remember to check bearing edges when you buy new drums. They can often be faulty, and drum companies are typically more than happy to replace the drums for you if they find that they sold a faulty product.

The top bearing edge is more important than the bottom, so pay close attention to that.

With that being said, all drums can be tuned and muffled to sound a certain way. If you plan on dampening your drums in any way, the type of bearing edges you have on them won’t make too much of a defining difference.

In that case, it’s better to look at what shell material and hardware the drums have rather than how their bearing edges are structured.